MODULAR PLANTS

Poultry

MODULAR PLANTS

Poultry

Home » Modular Plants » Poultry

Modular plant prefabricated and ready to use for the slaughtering of chicken, turkeys, guinea fowls, geese, ducks, rabbits. Built in accordance to the current health and hygiene regulations and to the law on the animal welfare as well as designed paying particular attention to the spaces optimization.

With our standard models it is possible to slaughter from a few animals to over 100 Capi/h, particularly suitable for small and medium-sized farms and country houses that want to enhance their product in a safe and scalable way.

Our modular plants can be customized with different options and according to the customer’s needs: they can be coupled with other modules or existing buildings to obtain the CE health mark, to increase storage, productivity or to diversify production.

The many options available for external finishing enable our modular plants to be Environmental Impact Assessment (EIA) complian

YOU CAN CHOOSE BETWEEN:

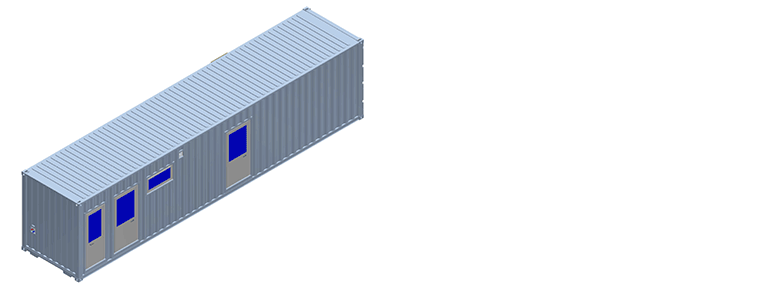

We manufacture the ISO modules from well-known shipping containers. The main structures, made of corrugated sheets and steel profiles, are lined internally with isothermal panels certified for food environments of adequate thickness to ensure excellent insulation and soundproofing. Suitable for naval transport as they are certified for this purpose.

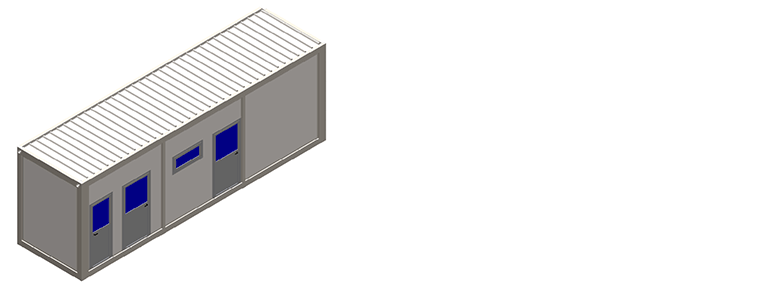

Prefabricated structures. Consisting of a strong skeleton of suitably sized hot-dip galvanised steelwork, covered with isothermal panels certified for food environments of adequate thickness to guarantee excellent insulation and soundproofing. The low weight of the Eco module is a guarantee of manageability while maintaining excellent performance in terms of solidity and economy.

The various exterior cladding options give the possibility to adapt our structures to possible environmental constraints related to protected areas such as National Parks or areas with landscape constraints. Wood, aluminium or Corten cladding are just some of the possible options.

Our solutions can be adapted and positioned on trailers for itinerant service management. This is an important function to be able to do work that can reach even the most remote areas - or to offer specific services directly in companies or production areas.

Sustainability and energy efficiency are increasingly important aspects. The possibility of exploiting the roof portion of the modules also allows in some cases to achieve energy independence of the workings, enabling savings and energy efficiency.

Our products are adaptable to any geographical context: from plains to urban areas, from mountainous areas to deserts. They are flexible in configuration according to the needs of the industry as well as customer-specific requirements.

The modular structure of our modules allows the customer to start with a single module while leaving the possibility, in the future, to expand or diversify production, integrating other new units or expanding those already installed.

Our solution, your business

Starting from 14.400,00€

A TURNKEY FOOD PROCESSING ROOM

Self Globe – a SINT partner – supports the development of agribusinesses worldwide through a systemic model of integrating all stages of the supply chain.

Sint Tecnologie S.r.l. Unipersonale

Località Molino, scn

62020 MONTE SAN MARTINO (MC)

Tel: +39 0733660132

mail: info@sinttecnologie.com